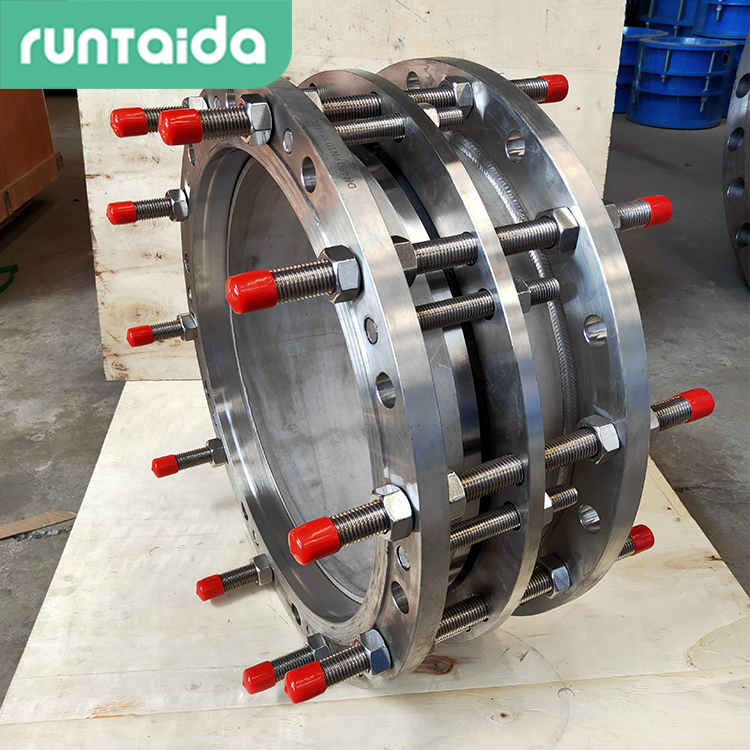

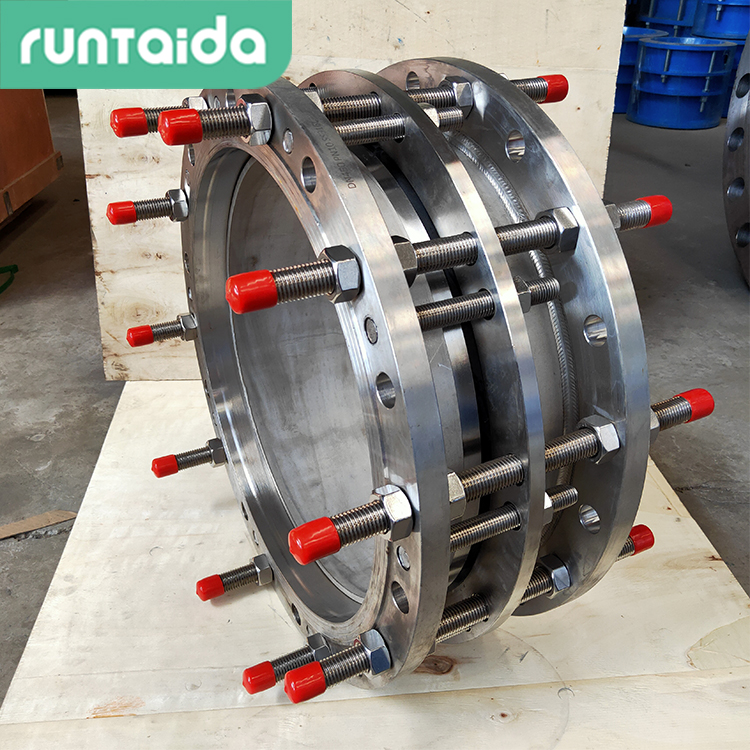

ANSI DN200 double flange insulating detachable steel expansion joint

- 品牌 runtaida

- 型號

Introduction of steel expansion joint

Double flange loose sleeve power delivery joint is consist of flange loose sleeve expansion joint, a connection short pipe, power delivery screw and other components, it can reduce the pressure ,thrust and blind plate force of the connector, it can also compensate the installaiton error of pipe, but double dlange loose sleeve powder delivery joint can't absorb the axial displacement.

Model introduction of steel expansion joint

The model of detachable double flange power delivery joint is VSSJAFC (CC2F), it's suitable for the pipeline which both sides are connected with the flange, when installing, adjust the installation length of the two ends of product and flange, tighten the gland bolts diagonally in trun, make them a whole, and retain a certain amount of displacement, convenient for adjusting according to the size of site in the installation and maintenance, the axial thrust can be transmitted to the whole pipeline at work.

Scope of steel expansion joint

Double flange loose sleeve power delivery joint is suitable for transporting sea water, fresh water, cold and hot water, drinking water, domestic sewage, crude oil, fuel oil, lubricating oil, refined oil, air, gas, the steam which temperature is not higher than 250°C, particle and powder other media etc.

Technical parameters of steel expansion joint

No

Name

Quantity

Material

1

Valve body

1

QT450-10,Q235A, 304, 316 etc.

2

Gasket

1

NBR

3

follower

1

QT450-10,Q235A, 304, 316 etc.

4

limited short pipe

1

Q235A, 304, 316 etc.

5

stud

n

Q235A, 35#, 304, 316 etc.

6

nut

Tn

Q235A, 20#, 304, 316 etc.

Main connecting dimension of steel expansion joint

Nominal diameter(DN)

External diameter(DW)

Shape dimension

Flange connection size

0.6 Mpa

1.0Mpa

L

L1

D

D1

N-Th.

b

D

D1

n-Th.

b

65

76

200

40

160

130

4-M12

16

185

145

4-M16

20

80

89

190

150

4-M16

18

200

160

8-M16

22

100

114

210

170

18

220

180

24

125

140

240

200

8-M16

20

250

210

26

150

168

265

225

20

285

240

8-M20

26

200

219

320

280

22

340

295

28

250

273

375

335

12-M16

24

395

350

12-M20

28

300

325

220

50

440

395

12-M20

24

445

400

12-M20

28

350

377

490

445

26

505

460

16-M20

30

400

426

540

495

16-M20

28

565

515

16-M24

32

450

480

595

550

28

615

565

20-M24

32

500

530

645

600

20-M20

30

670

620

20-M24

34

600

630

240

755

705

20-M24

30

780

725

20-M27

36

700

720

860

810

24-M24

32

895

840

24-M27

40

800

820

350

60

975

920

24-M27

34

1015

950

24-M30

44

900

920

1075

1020

24-M27

36

1115

1050

28-M30

46

1000

1020

1175

1120

28-M27

36

1230

1160

28-M33

50

1200

1220

370

1405

1340

32-M30

40

1455

1380

32-M36

56

1400

1420

1630

1560

36-M33

44

1675

1590

36-M39

62

1600

1620

380

1830

1760

40-M33

48

1915

1820

40-M45

68

1800

1820

2045

1970

44-M36

50

2115

2020

44-M45

70

2000

2020

400

2265

2180

48-M39

54

2325

2230

48-M45

74

2200

2220

2475

2390

52-M39

60

2550

2440

52-M52

80

2400

2420

2685

2600

56-M39

62

2760

2650

56-M52

82

2600

2620

450

80

2905

2810

60-M45

64

2960

2850

60-M52

88

2800

2820

3115

3020

64-M45

68

3180

3070

64-M52

94

3000

3020

3315

3220

68-M45

70

3405

3290

68-M56

100

3200

3220

3525

3430

72-M45

76

This is the products we processing and exported to the united states.

Introduction of our factory

Gongyi Runda Pipeline Manufacturing Co.,Ltd. is located in Xicun village pipeline equipment industrial park, Xicun town, Gongyi city, Henan province, China mainland, covering an area of 20,000 square meters,The company currently has the largest diameter 4000mm pipeline equipment production capacity,The main products are: steel expansion joint, flexible waterproof casing, large caliber flange, double flanges transmission expansion joint, sleeve compensator, bellows pipe compensator (corrugated pipe compensator), non metallic compensator, rubber expansion joint, direct current medium without thrust compensator, flexible telescopic pipe, etc,annual production capacity of 12000 pieces.